- Home

- About Us

-

Product Center

-

Stainless steel filter element

-

Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

- Stainless steel composite mesh filter element

-

Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter element

- Stainless steel perforated plate mesh filter bag

-

Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

- Stainless steel folded mesh filter element

-

Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

- Stainless steel wedge-shaped wire filter element

-

Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel micro-porous arc-shaped screen mesh

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

- Stainless steel microporous filter element

-

Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

- Stainless steel fiber felt filter element

-

Stainless steel composite mesh filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

-

Stainless steel straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Stainless steel straight-through filter

- Precision filter

- 10-inch straight-through filter

- Sanitary grade filter

- Straight-through pipe filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- Equipment category

- Industry application

-

Stainless steel filter element

- Solution

- News Center

- Contact us

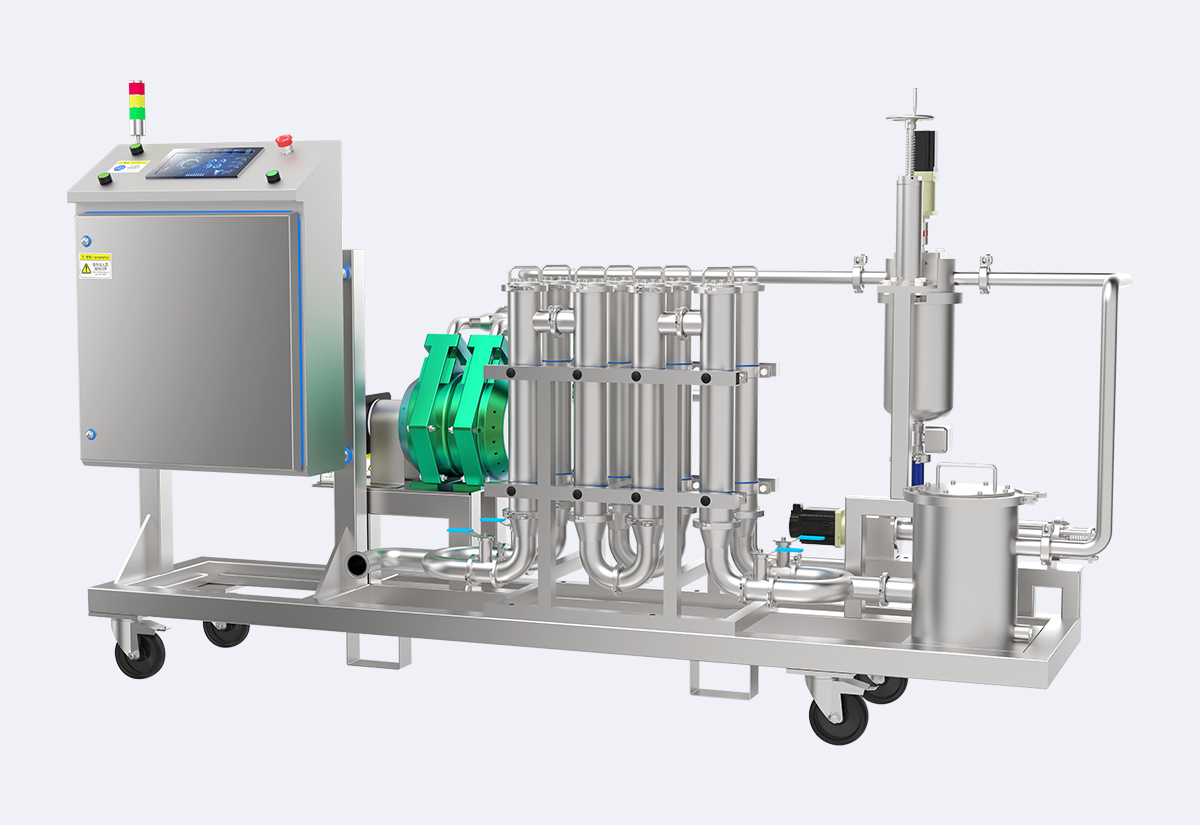

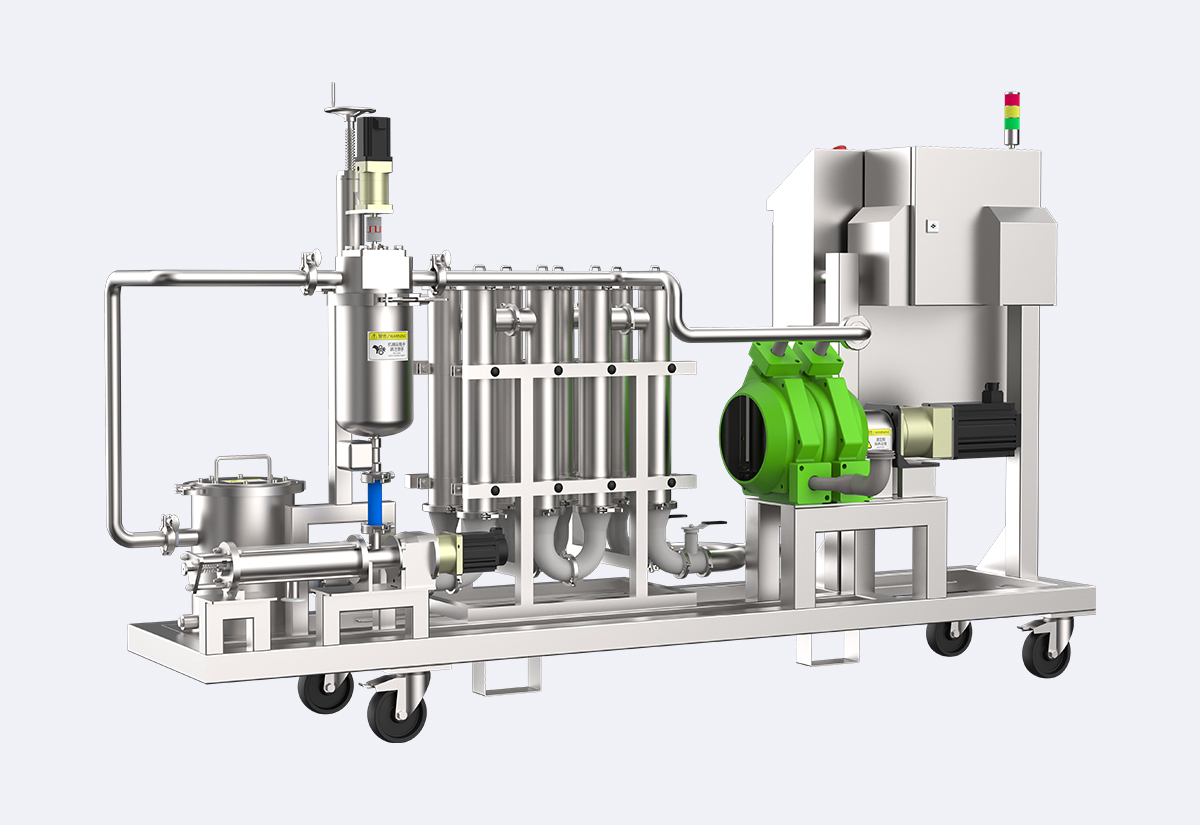

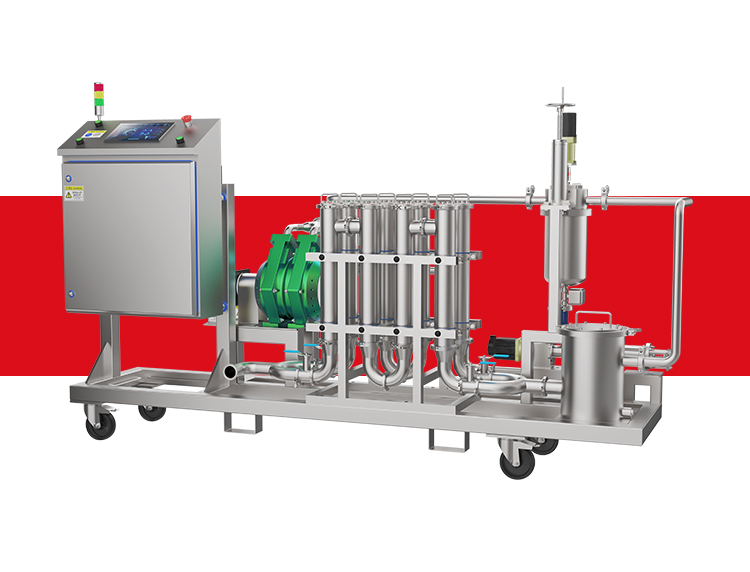

Pre-filling filter group

The magnetic filter group before filling fruit and vegetable beverages is a key device used to remove magnetic impurities from fruit and vegetable beverages, which can ensure the quality of the beverages and the normal operation of subsequent filling equipment.

I. Core Working Principle

By using the strong magnetic field generated by permanent magnets, when fruit and vegetable beverages pass through the filter group, the ferromagnetic impurities in them, such as iron filings and rust, will be adsorbed by the magnetic rods, thus achieving separation from the beverages. Meanwhile, the filter screen can filter out some non-magnetic solid particle impurities.

Ii. Core Configuration and Technical Parameters

| Project | Parameter | Parameter |

| Overall dimensions | Approximately 2.4 meters in length, 1.0 meter in width and 1.4 meters in height | |

| Production capacity | Five tons per hour | Different materials result in different production capacities |

| Control system | Siemens PLC | |

| Scraper motor | 0.75kw | Servo control |

| Vacuum conveying | 1.8Kw | Servo control |

| Vacuum conveying | 6000-12000Gs | Adjust as needed |

Iii. Core Product Advantages

Ensuring product quality: Removing magnetic impurities from fruit and vegetable beverages can prevent impurities from affecting the color and taste of the beverages and reduce the risk of product recalls caused by impurities.

Protect filling equipment: Prevent magnetic impurities from entering precision components such as filling valves, avoid equipment blockage or wear, ensure the normal operation of filling equipment, and reduce equipment failure rates and maintenance costs.

Iv. Applicable Scenarios

The equipment is widely applicable to various large-scale beverage production enterprises, especially suitable for:

HPP juice production line: such as freshly squeezed orange juice, apple juice, strawberry juice and other additive-free juice production;

Compound fruit and vegetable beverage factory: For precise juicing and flavor fusion of various fruit and vegetable raw materials;

Functional beverage enterprises: Production of high-end beverages that need to retain specific nutrients (such as antioxidants and vitamins);

Fruit and vegetable deep processing factory: Providing pre-juicing processing for products such as fruit puree, jam, and concentrated fruit juice.

V. Customized Services and After-sales Assurance

According to the production capacity scale, raw material characteristics and product positioning of different beverage factories, customized solutions can be provided: including capacity expansion, process module upgrading (such as low-temperature crushing, aseptic conveying), seamless integration with existing production lines, etc. At the same time, we provide full life-cycle services, covering equipment installation and commissioning, operator training, remote operation and maintenance support, regular inspection of core components, etc., to ensure the long-term stable operation of the equipment.